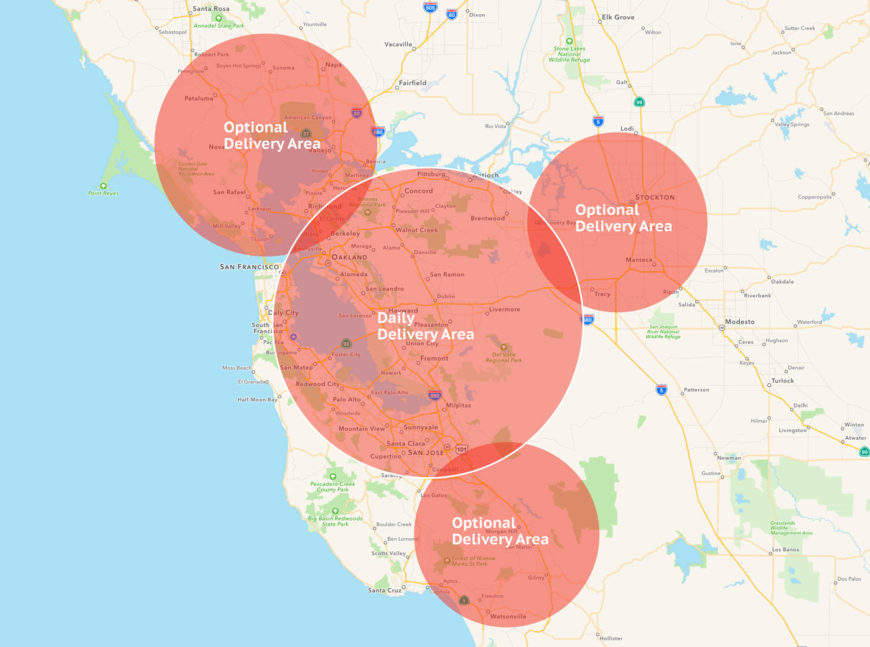

Do you deliver finished products?

We’re willing to deliver your parts anywhere. Our normal delivery area is from Petaluma (N) to San Jose (S), and from South San Francisco (W) to Livermore (E).

What tool steel should I use for my dies?

Good tool steels to use with dies are A-2, D-2, or S-7.

When do you run tool steel?

We typically run tool steel twice a week, on Monday and Wednesday nights. If you absolutely, positively need it run overnight, we will help you. Call us.

What is the best material for Nitriding?

We feel nitralloy is the best materials for Nitriding. Feel free to contact us to learn about other alternatives we can use.

What are the steps for hardening steel?

There are three steps for hardening steel, which are heating, quenching and tempering. Those same steps are used for aluminum also.

What is the best material for Carburizing?

The best metals for carburizing are 8620 and 9310 steel.

What’s the difference between a metallurgist and a materials engineer?

A metallurgist focuses primarily on heavy and light metals. A materials engineer focuses on metals, plastics, and other materials. Generally speaking, the degree of “Metallurgist” has been replaced by the degree of “Materials Engineer” or “Materials Scientist” at most colleges.

Do you have a specialized metallurgist I can talk with?

Yes, we have 3 materials engineers you can talk with. We also have an industrial engineer, and a mechanical engineer.

Will material change size during the heat treating process?

Generally it may. There are many reasons that material changes size or distorts, but we’ll need more information to give you an exact answer.

What are wear resistance applications?

Wear resistance applications include types of Case Hardening such as nitriding and carburizing. A few other wear resistance applications like Induction Hardening and Carbonitriding are also ways to harden the surface of a material.

Who built your website?

Our original website was designed and coded by Divid Designs. The video was made by Nathaniel Kohfield. Our current website was ported into WordPress by ThomasNet. All content was built and reviewed by us at ThermoFusion.

What Northrop SPARs do you maintain?

We maintain the following SPARs:

– C3825 – carbonitride steel

– C3783 – carbonitride steel

– C3618 – carbonitride steel

– A3896 – malcomizing (nitriding) stainless steel

– A2016 – nitriding steel and stainless steel

– A2011 – general heat treatment of steel, aluminum and copper

What are your Supplier Flow Down Requirements?

Please click on the document listed below for a printable page of our Flow Down Requirements.

Top