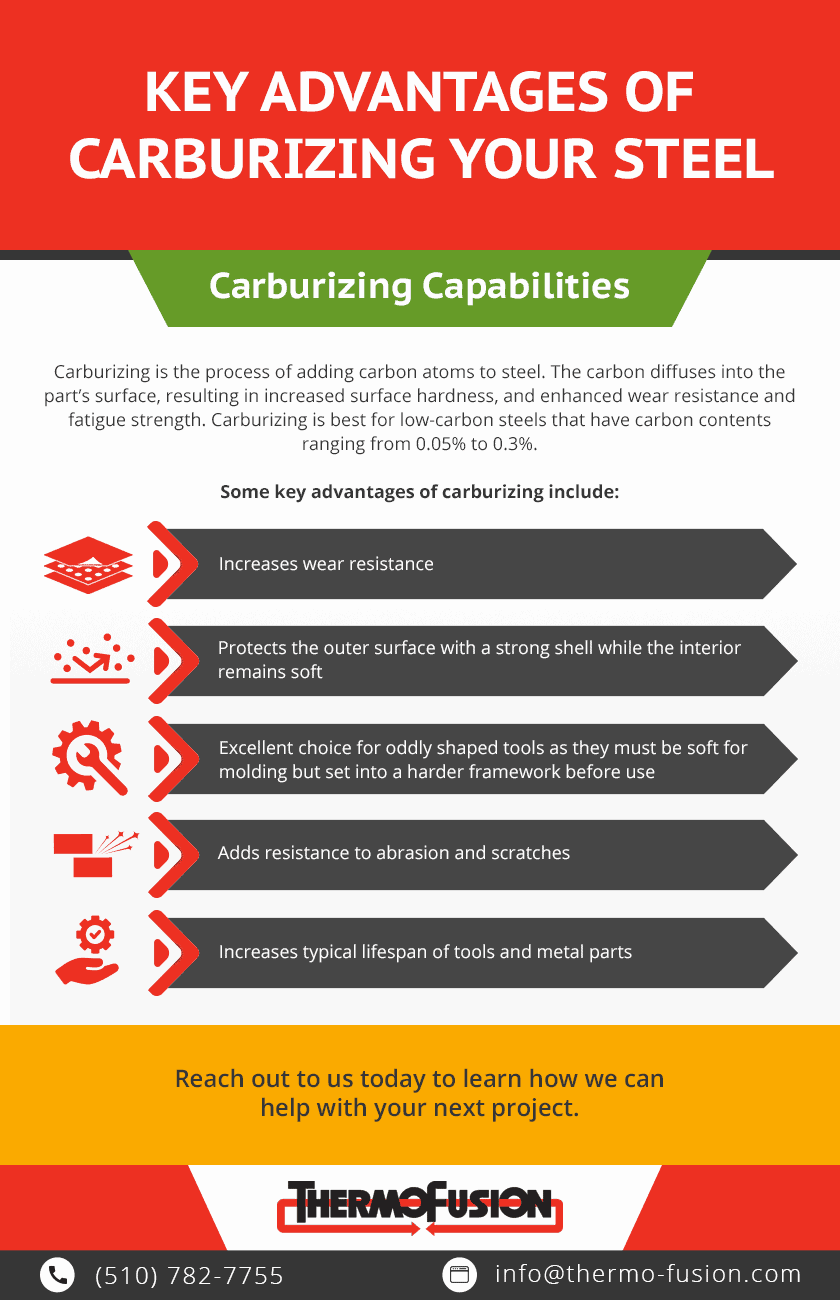

ThermoFusion is a heat treating and brazing company in the Bay Area that offers many heat treating and brazing solutions, including carburizing. Carburizing is the process of adding carbon atoms to steel. The carbon diffuses into the part’s surface, resulting in increased surface hardness, and enhanced wear resistance and fatigue strength. Carburizing is best for low-carbon steels that have carbon contents ranging from 0.05% to 0.3%.

ThermoFusion is a heat treating and brazing company in the Bay Area that offers many heat treating and brazing solutions, including carburizing. Carburizing is the process of adding carbon atoms to steel. The carbon diffuses into the part’s surface, resulting in increased surface hardness, and enhanced wear resistance and fatigue strength. Carburizing is best for low-carbon steels that have carbon contents ranging from 0.05% to 0.3%.

How deep the carbon can disperse into the metal’s surface during carburizing depends on the type of material, level of carbon in the atmosphere, the temperature used, and how long the material is exposed to the high carbon environment at that temperature. Carburizing is complete when the metal is rapidly cooled, or quenched, which locks the carbon into place.

Carburizing Capabilities

ThermoFusion offers many carburizing capabilities that can meet your specifications. We carburize (or nitro-carburize) materials such as 12L14, 1018, and 8620 steels. We have air temper and oil quench equipment and endothermic furnaces that reach temperatures between 1200℉-1750℉.

Some advantages of carburizing include:

- Increases wear resistance

- Protects the outer surface with a strong shell while the interior remains soft

- Excellent choice for oddly shaped tools as they must be soft for molding but set into a harder framework before use

- Adds resistance to abrasion and scratches

- Increases typical lifespan of tools and metal parts

ThermoFusion Can Handle All Your Carburizing Needs

At ThermoFusion, we have over 40 years of experience in carburizing and other heat treating and brazing techniques. We are ISO9001:2015, AS9100D, and Nadcap certified, and our metalworking experts are dedicated to exceeding customer expectations by quickly and efficiently providing high quality services that suit your metallurgical needs.

Contact Us today for help with your next project!

Top